Our CFD team developed a new CFD tool for analyzing and optimizing sailboats and WASP systems for the nautical and maritime industry, optimizing hydrodynamic and aerodynamic performance in assessments with +6 Degrees of Freedom. This configuration includes the ship dynamic rotations and translations plus the degrees of freedom of the aerodynamic propulsion systems. The project combined advanced CFD simulations with propulsion control logics to provide powerful insights for the design and improvement processes of high performant ships and sailboats.

Year:

Client:

Team:

Technical Specs:

The optimized equilibrium points produced by our in-house VPP tools must be validated in a realistic environment, where aerodynamic and hydrodynamic forces simultaneously define the vessel’s attitude and performance, especially for ships combining wind propulsion devices with conventional propellers. Too often, these models are built separately and key coupled effects are missed. That’s why we use a fully coupled CFD setup, first as a validation tool and then as an optimization lever: it reproduces equilibrium in simulation, avoids simplification errors, and delivers the most accurate numerically based solution.

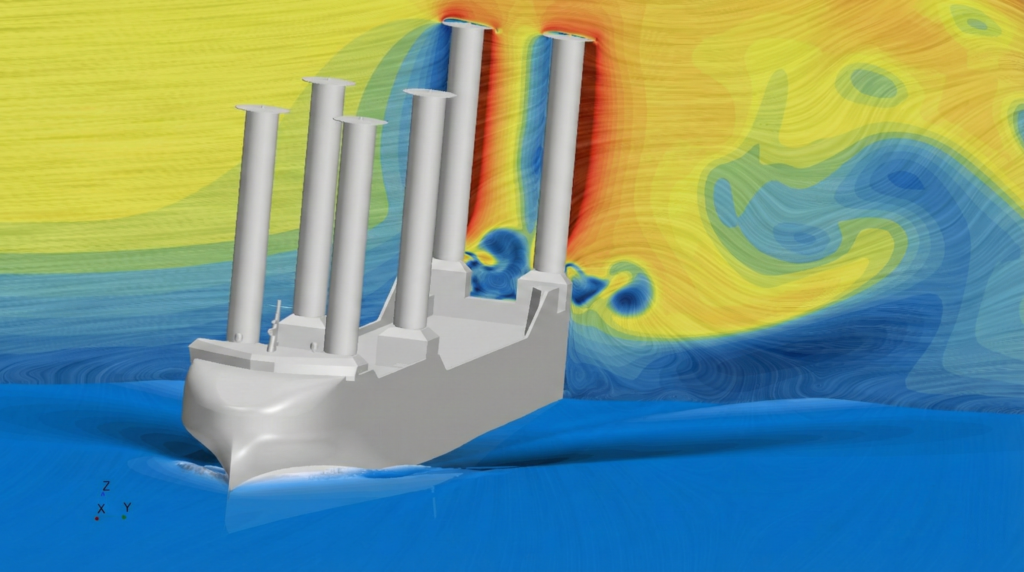

Our STAR-CCM+ workflow is built around full-scale, transient, multiphase free-surface simulations (VOF) to capture the coupled interaction between air, water, and the vessel in realistic operating conditions. The ship is solved with +6-DoF Dynamic Fluid–Body Interaction (DFBI), so surge, sway, heave, roll, pitch, and yaw emerge from the computed loads rather than being imposed. We include controllable propulsion devices directly in the model, e.g., Flettner rotor RPM and conventional propellers, so thrust, interaction effects, and attitude are evaluated consistently within one coupled setup. High-quality mesh strategies keep accuracy high while enabling robust convergence for complex manoeuvres and sea states.

This new CH CFD workflow provides a robust way to verify that our in-house VPP predictions match the real behaviour of wind-assisted propulsion ships. By simulating the full aero-hydrodynamic equilibrium, we can quantify hydrodynamic loads while operating at sea and isolate the thrust contribution of each Flettner rotor. The result is a detailed breakdown of propulsion demand across rotors and propellers, plus a powerful visual understanding of interaction effects between the WASP system, the hull, and the rotors themselves. This insight is especially valuable during early layout definition, where efficiency gains depend on getting system integration right.

The optimized equilibrium points produced by our in-house VPP tools must be validated in a realistic environment, where aerodynamic and hydrodynamic forces simultaneously define the vessel’s attitude and performance, especially for ships combining wind propulsion devices with conventional propellers. Too often, these models are built separately and key coupled effects are missed. That’s why we use a fully coupled CFD setup, first as a validation tool and then as an optimization lever: it reproduces equilibrium in simulation, avoids simplification errors, and delivers the most accurate numerically based solution.

Our STAR-CCM+ workflow is built around full-scale, transient, multiphase free-surface simulations (VOF) to capture the coupled interaction between air, water, and the vessel in realistic operating conditions. The ship is solved with +6-DoF Dynamic Fluid–Body Interaction (DFBI), so surge, sway, heave, roll, pitch, and yaw emerge from the computed loads rather than being imposed. We include controllable propulsion devices directly in the model, e.g., Flettner rotor RPM and conventional propellers, so thrust, interaction effects, and attitude are evaluated consistently within one coupled setup. High-quality mesh strategies keep accuracy high while enabling robust convergence for complex manoeuvres and sea states.

This new CH CFD workflow provides a robust way to verify that our in-house VPP predictions match the real behaviour of wind-assisted propulsion ships. By simulating the full aero-hydrodynamic equilibrium, we can quantify hydrodynamic loads while operating at sea and isolate the thrust contribution of each Flettner rotor. The result is a detailed breakdown of propulsion demand across rotors and propellers, plus a powerful visual understanding of interaction effects between the WASP system, the hull, and the rotors themselves. This insight is especially valuable during early layout definition, where efficiency gains depend on getting system integration right.

30% more efficient sport yacht developed with Bluegame / Sanlorenzo.

Multiphase and multi degrees of freedom CFD simulation setup for optimization and validation of performance predictions related to sailing yachts and commercial vessels with WASP devices

Accurate Wind Performance Prediction: A high-fidelity Ship Digital Twin for Wind-Assisted Power Performance Prediction and Voyage Optimisation.

During the 33rd America’s Cup cycle, Mario Caponnetto contributed to hydrodynamic assessment workstreams aligned with the BMW Oracle wing-sail platform, the configuration that ultimately won the Match. This milestone marked the shift toward aero-hydrodynamic integration in Cup design culture.

BMW Oracle Racing

America’s Cup / Aero-Hydro Integration / Performance Engineering

In 2021, Caponnetto Hueber led the CFD, foil design, and hydrodynamic engineering for the AC75 of Luna Rossa Challenge, the eventual Prada Cup winner. We deployed multiscale CFD and aero-hydro coupling to ensure optimum lift and control. Rapid iteration delivered performance gains under tight competition timelines.

Luna Rossa Challenge

Racing Concept / CFD / Foil Design